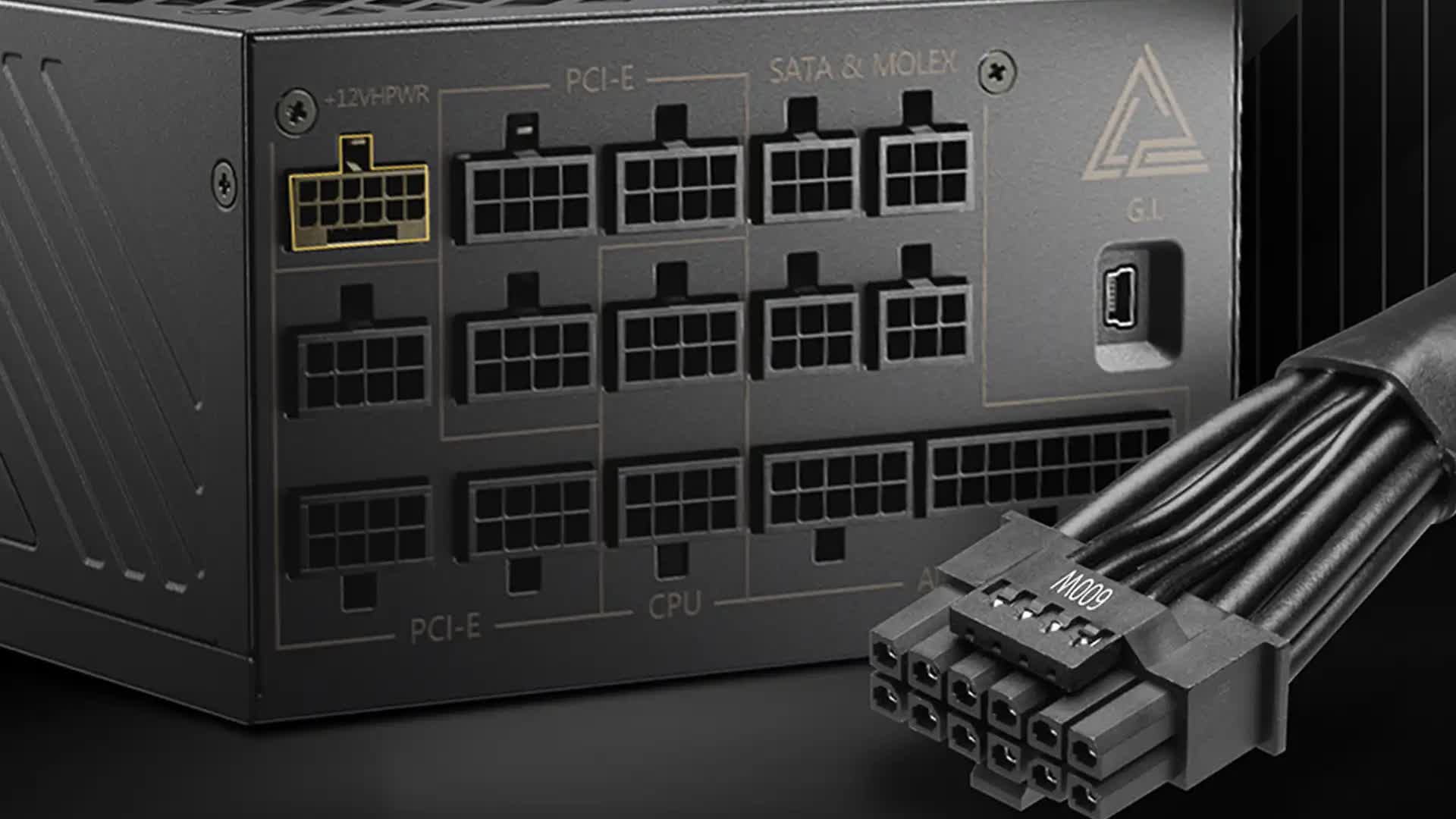

Highly anticipated: The curious case of the melting connector has been a hotly debated topic among RTX 4090 owners, manufacturers, and independent third parties since the first case was reported in October of last year. Manufacturers have pointed out that users may not have fully seated the connector, while users and reviewers have blamed the manufacturers for a faulty implementation. Both parties have also highlighted potential shortcomings in the overall design of the connector. Now, a proposed change to the connection's specification could put an end to the debate once and for all.

Igor Wallossek of Igor's Lab has been at the forefront of the 12VHPWR connector issue since problems began surfacing last October. In his latest report, Wallossek provides some much-needed good news for RTX 4090 owners and 12VHPWR connector users: a real solution could be on the way soon.

A revision to the current connector's standard was recently released in a draft engineering change notice filed by the Peripheral Component Interconnect Special Interest Group (PCI-SIG). The new specification aims to address the design issues contributing to melting and connection failures associated with the RTX 4090.

According to the new specification and Wallossek's report, the new 12V-2×6 connector would be compatible with older graphics cards that utilize the original 12VHPWR header, power supply connectors that use the legacy 12VHPWR connection, as well as any existing adapters.

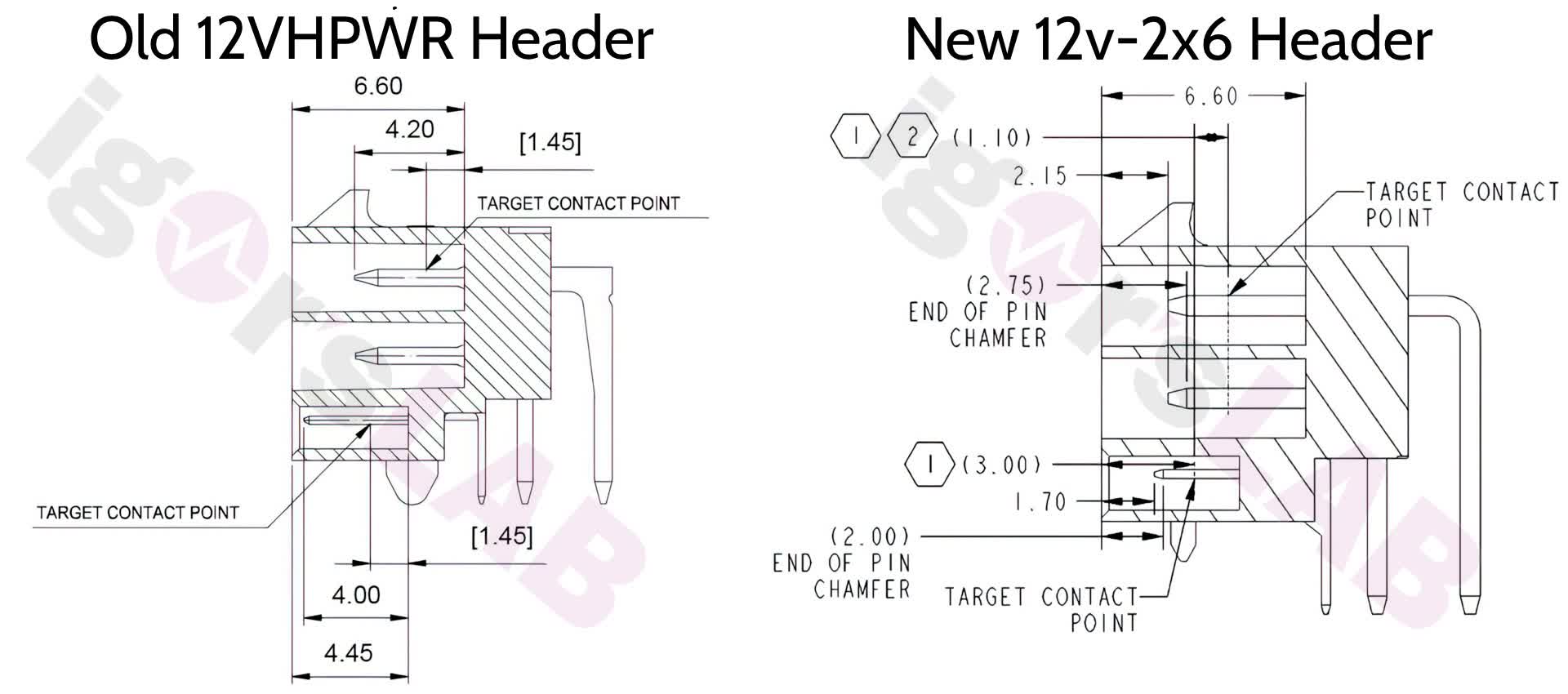

The new 12V-2x6 power connector would maintain the same number of contacts as the existing 12VHPWR power connector. However, the new specification would require 12 larger contacts to carry the power, with four smaller sense pins used for sideband signals. While the previous power connector had a maximum rating of 600W, the limit on the new 12V-2x6 power connector is 675W (600W for the connector and an additional 75W from the PCIe slot).

The legacy and proposed connectors may appear quite similar at first glance. However, users will be able to distinguish between the old and new styles based on their unique identifiers. The legacy 12VHPWR power connectors will have the H+ marking on the top of the connector. On the other hand, the new 12V-2x6 power connector will instead use the H++ identifier.

Like its predecessor, the new specification includes specific requirements for wires and cabling. As mentioned in Wallossek's report, manufacturers can prevent unnecessary stress on the crimp contacts by ensuring that cable bundles are not bent, stretched, or restricted immediately after exiting the connector. Wiring manufacturing and practices are provided in the IPC/WHMA-A-620 standard, which provides guidelines and requirements for the production of cables, wires, and other associated assemblies. The standard describes the materials, test procedures and acceptance criteria for creating crimped, mechanically secured, and soldered connections.

The report provides a detailed account of several differences between the current 12V implementation and draft 12V-2x6 specification, including variances in connectors, temperature thresholds, and power handling and delivery. A comprehensive summary of these changes, along with additional technical information and diagrams from the draft engineering change document, can be foudn in the original report from Igor's Lab.

Image credit: Igor's Lab