Big quote: "Goodyear wants the tire to be an even more powerful contributor to answering consumers' specific mobility needs," said Mike Rytokoski, Vice-President and Chief Marketing Officer, Goodyear Europe. "It was with that ambition that we set out to create a concept tire primed for the future of personalized and convenient electric mobility."

Tire manufacturers come up with a lot of creative ideas for moving your car down the road, even if most never see the light of day. Five years ago, Goodyear had a concept for a tire that would charge electric vehicles as they moved. Last year it came up with the Aero, a unibody tire-wheel turbine imagined to transition from road to air for flying cars.

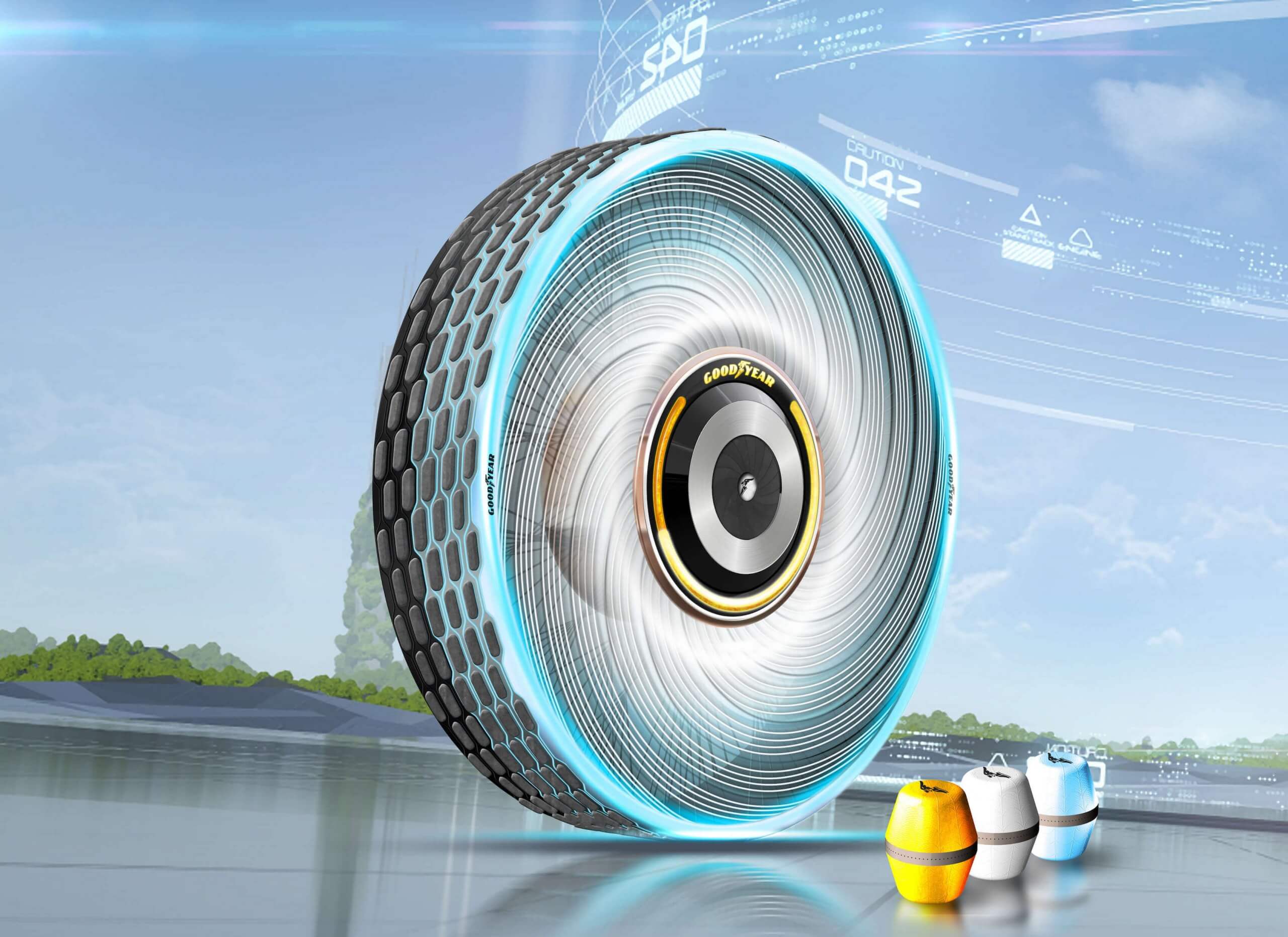

In an age of 3D-printing, it was inevitable that tire makers would employ the technology, which Michelin did in 2017 for a puncture-proof biodegradable tire made from orange peels and wood chips. Now Goodyear has flipped 3D-printed tires on its head with a concept tire that prints tread from the inside.

The reCharge is a tire that will never go flat, never need replacing, and never need to be rotated. The concept wheel uses a renewable compound reinforced with fibers inspired by spider silk. The material is extremely durable and completely biodegradable. The synthetic rubber comes in rechargeable capsules inserted into the wheel hub without having to remove the tire.

The way it would work is the wheel would contain a solution of the compound that would be squeezed through small tubes to the surface of the tire. Artificial intelligence would control the flow so that the material only goes to where it is needed. Once exposed to air, the compound cures into a rubber-like material. The AI also stores driver profiles to create a customized compound that adapts to driving style, weather, and road conditions. It is unclear if this customization occurs in real-time, or if the capsules have to be replaced with the custom fluid from the dealer.

Of course, this is just a concept, so don't expect to see it anytime soon, if at all. While Goodyear already has the telemetry and algorithms required, the compound is extremely expensive to produce.